Our History

Dynatron capacity for continuous innovative design, coupled with keen perception of the market needs has resulted in a major progress and new higher standards being set in design and efficiency of various areas of the bottling line including carbonated systems, container and bottle washing and electronic controls and monitoring systems. The continuing aim of Dynatron is to maximise for the client his production line efficiency whilst simultaneously reducing operating costs. The result is a range of ergonomically designed machines requiring a minimum operator involvement. Dynatron many years of unparalleled experience, coupled with modern production facilities, extensive research and development and stringent quality control standards combine to provide the foundation for the ultimate in technology for the bottling and packaging industries.

Why Choose Us

Major importance to energy reducing features when design of machines thus making operational costs economical. Technology equivalent to global OEM companies and international standards where fabrication, workmanship, and Quality is concerned Technical collaboration with MNC OEM Simonazzi, has engraved the international manufacturing processes and designs at its facilities. Existing customers are MNC which ensures Dynatron capability to execute large projects. Whether it is a up gradation of an existing model of machine, refurbishment of machines or a new development, our work starts by verifying the same from the drawing board and bill of materials, where dimensions of components, tolerance, grades of material, strength, electrical drawings, automation, instrumentation and aspects required to successfully deliver to the customers a machine which is not over designed or under perfoirmaing. This way the clinet is ensured value for his money and with dynatron startaget of building long term client relationship and loyalty

Our Management

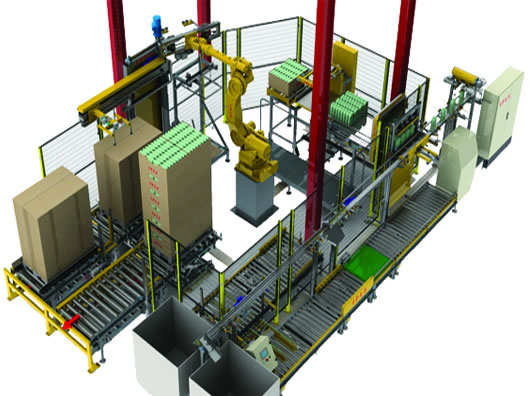

What We Do

INSTALLATION

Faster installation of its machines, to reduce downtime of plant when replacing old designs. This is done by Dynatron modular design for easy transport / assembly / dismantling. Dynatron know-how and experience of highly trained personnel, they guarantee success and mean that more than simple being a system and line supplier we are considered as a partner. What Dynatron really wants is to create value for their customers by, for example: Reducing line installation and start up times reaching contractual efficiency in a very short time maintaining line efficiency at high levels even when Dynatron technicians are no longer on site.

RESEARCH AND DEVELOPMENT

Dynatron core strength being machihne design,its philosophy has been to incorporate the customer requirements right at the machine drawing stage. Dynatron considers to be of fundamental importance and a major factor in the success of the product Dynatron follows the below methods to achive thsi A dedicated team of technicians and engineers with a lot of experience in the bottling and packaging field. Dynatron has technical colloberations with different companies in Europe for its equipments , technology and software, which ensures that Dynatron has a continuous process of technological upgradation and advantage when compared to any glpbal suplier of bottling machines . Dynatron philosophy of associating with students from Universities in order to acquire and make the best use of the fresh talent and latest technique technology in testing of its raw materails strengths softwares, selection of materils , pararmeters like distribution of load and simulations for critical assemblies.